We provide a range of high quality precision coatings designed to increase the lifespan, appearance and performance of your components.

Whether you are specifying finishes on new parts, looking to resolve a persistent problem, or looking for a reliable subcontracter, we can help. Our coatings, which include Electroplating, Electroless Plating and Sprayed Coatings, improve performance and solve a number of common industrial problems such as corrosion, wear, friction and hardness. We offer a wide variety of finishes, ensuring that coating your components will guarantee that they look great too.

At SBM, we strive to keep

our quality, service and standards high using integrated Quality

Management Software that traces and monitors the progress of parts in

the facility ensuring full traceability at all times.

Our coatings are completed to the highest industry standards to ensure that they stand the test of time.

Whether you are looking for batch orders, recurring jobs, or a specialist one-off item, we aim to accommodate.

Our highly skilled team boasts years of experience and a reputation for achieving excellent results.

Conveniently situated in central Carlisle, we are in the ideal location

to service businesses accross the North of England and Southern

Scotland. We provide delivery and collection for our clients and are

easily accessible via the M6, and A69 if you wish to come to us.

We also offer a FREE daily delivery and collection service for the North

East, please ask for details.

At SBM Coatings we pride ourselves on our products, our service, and our people.

Contact us today to discuss your requirements and for your free no obligation quotation

At SBM Coatings we offer a variety of quality coatings for our small and large commercial clients. Whether it's electroless nickel plating for components on an oil rig or zinc plating for a small project, contact us to find out how our skilled team can assist you.

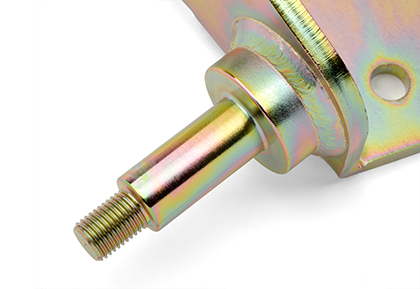

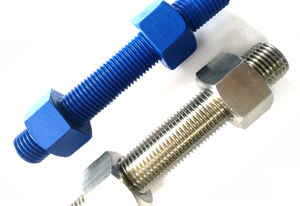

Probably the most common electro-deposited coating. Used in manufacturing the world over, zinc plating works to protect the underlying metal by acting as a sacrificial anode. The benefit this provides for you is a bright, anti-corrosion finish that - unlike painting - will not cause build up on threads and complex geometries.

Zinc plating is the ideal solution for your fasteners and parts. At SBM Coatings we have yellow, blue (clear) and black passivate available. For a decorative alternative to wet painting, contact our expert team today.

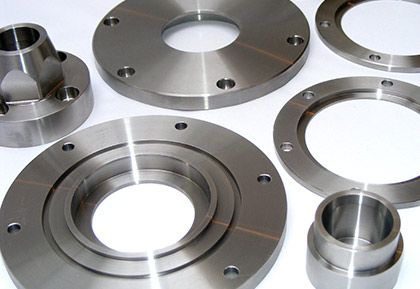

Like Electroplating, ENP prevents corrosion and wear of a metal or plastic components. An electric current is not required for nickel plating, making for an even deposit and allowing for deposits to be formed on non-electrical surfaces.

Our immersion

coatings have benefits for commercial clients working in a variety of

sectors, such as Oil and Gas, Automotive, Marine, Renewables, Nuclear

and General Engineering.

Applied as a wet film then cured at specific temperatures, these resin bonded lubricants are designed to replace toxic copper slip and MoS2 grease and work over a wide range of temperatures. We offer a range of different options in various colours; our most popular being Xylan 1070, 1010, 1425 and Everlube 1PX1.

Embrittlement is caused by nascent hydrogen penetrating surface cracks or discontinuities and becoming trapped. This can occur as a result of plating or other processes and can cause weakness in the metal. Although usually only expected on high tensile fasteners there is a risk of catastrophic ductile fracture occurring on parts with hardness over 320HV.

In order to avoid this risk, we can provide you with an expert hydrogen de-embrittlement process. For tensile fasteners with hardness equal to or over 380HV we would recommend some form of dry film lubrication.

Vapour Blasting is an abrasive blast cleaning process. A mixture of water and glass beads are combined to form a very fine slurry before being blasted onto the component via compressed air and slurry pump. Unlike dry blasting, the presence of water and use of a detergent creates a lubricating cushion that mildly polishes, degreases and protects the surface.

At SBM we use our Vapour Blasting Application as a pre-Treatment to High and Medium Phosphorus ENP to provide a all round Uniform Finish unless otherwise stated. However it also has a brilliant application for Satinising Stainless Steel and other metal components.

This process increases the corrosion resistance on steels containing more than 11% chromium by dissolving exogenous iron particles, oxides, scales or other deposits which may adversely affect the surface, metallurgical, sanitary or mechanical properties of components. It prevents the iron contamination of process fluids, foods and pharmaceuticals by the formation of an inert (passive) layer of chromium (III) oxide.

This can be a huge benefit to those in the food and beverage, medical and chemical industries, preventing rouging and eliminating rust spots on steel components.

Electropolishing, also known as electrochemical polishing, anodic

polishing, or electrolytic polishing, is an electrochemical process that removes material from a metallic

workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish.

It is used to polish, passivate, and deburr metal parts.

Manganese Phosphate is a treatment that

utilises Manganese Salt, Phosphoric Acid and an accelerator, all of

which are applied at very high temperatures.

This conversion coating process involves the dissolution of the base

metal, and subsequently forms part of the actual coating - offering

excellent wear resistance.

Chemical blacking is a metal finishing

process that provides most ferrous surfaces with a protective and

decorative black coating.

The formation of the black oxide coating strengthens the component with

impressive anti-chip and anti-scuff properties, and the process does not

alter the dimensions of the component.

To order our products, ask about specifications or get hold of a free quote, please give us a call, or drop through an email.

We always aim to respond as promptly as possible.

+44(0)1228 819 324

info@sbmcoatings.com

Monday to Thursday 8.00 am to 5.00pm

and Friday 8.00am till 3.00pm

Unit 5, Currock Road Trade Centre,

Currock Road, Carlisle,

Cumbria, CA2 5AD